Ball Check Valves

TVI has been a leading provider of high-quality valves and accessories for more than 30 years. Our years of industry experience, dedication to our customers, and partnerships with world-renowned valve manufacturers allow us to provide a diverse range of industries with high-level valve solutions.

Every member of the TVI team works in tandem to provide fast order turnarounds and superior customer service. We offer a wide range of quality valve solutions, including ball check valves.

Ball Check Valves from TVI Valves

Ball check valves provide backflow checking inside a piping system. Pressure lifts the valve in a conical shaped valve body, allowing for flow in the designed direction and using gravity to close the valve when flow pressure decreases. TVI provides two different categories of ball check valves to our customers.

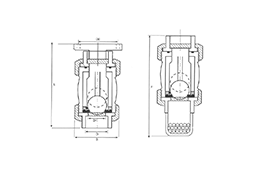

½” to 4″ Ball Check Valves

Designed with full-length ribs to provide maximum flow and minimum pressure drop, these solid thermoplastic valves provide a full-circle, resilient seat and operate under working pressures up to 150 psi.

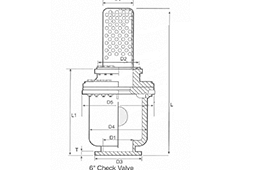

6″ and 10″ Ball Check Valves

Both of these valves include similar design features to our smaller valves, but with lower working pressures of 85 psi (6″) and 42 psi (10″). Of note, the body of our 10″ valve is constructed from fiberglass reinforced thermoplastic instead of thermoplastic PVC.

Ball Check Valve Operations and Maintenance

Ball check valves open to allow flow in the designed direction. The back pressure of the fluid reseats the valve using gravity when flow pressure drops, preventing backflow.

Infrequent maintenance requirements are a primary advantage offered by these valves. Component replacement is necessary in nearly all valves due to part wear. In these instances, replacement of components usually requires shutting off line pressure and removing the valve.

Our ball check valves only require loosening the coupling nut to access. This provides easy access to all valve components, enabling in-line replacement and facilitating minimal downtime for maintenance and repair operations.

What are the Different Types of Check Valves?

Check valves are essential to providing flow in only one direction and preventing backflow under a variety of circumstances, environmental conditions, and flow materials. As such, TVI carries a diverse selection of check valves to suit the needs of a diverse field of industries and applications. Our inventory includes various sizes of each type of check valve, including:

- Ball Check Valves open due to flow pressure in the direction of flow and close due to back pressure from flow. These valves are quite common, and their uses include aquariums, chemical processing, landfills, mining, power plants, swimming pools, and water treatment, among many others

- Swing Check Valves open using flow pressure in the direction flow and swing closed when flow pressure decreases. Common applications for swing check valves include pump backflow prevention, tank inlets/outlets, mitigating water hammer, one-way mixing, pressure balancing, and process intakes.

- Wafer Check Valves operate in similar fashion to swing check valves, but they have no valve body and fit between two flanges, saving space. Common instances for wafer check valves include mitigating water hammer, tank inlets/outlets, preventing pump backflow, one-way mixing, pressure balancing, or limited-space process intakes.

Contact TVI for Your Ball Check Valve Needs

Check valves are an important component for controlling unidirectional flow within a piping system. Ball check valves provide a low maintenance solution for instances where supervision is infrequent. TVI Valves provides high-quality ball check valves in a range of standard sizes to fit specific customer needs

Please contact us for more information about ball check valves or the full product line of valve solutions available from TVI.