Plastic Valves

TVI has over three decades of experience providing a variety of industries with high-quality valves and accessories. By partnering with us for their plastic valve needs, customers benefit from our:

- Experienced team with extensive knowledge about industrial valves

- Global partnerships with reputable valve manufacturers

- Dedication to customer service and engagement

- Fast turnaround and competitive prices

Our full-service valve solutions, ranging from product selection to shipping, provide customers with the best value at the given price point. Whether you need a plastic butterfly or Y-sediment strainer valve, we can meet your valve needs.

Types of Valves Available at TVI

As a full-service plastic valve supplier, we offer a broad selection of thermoplastic valves to suit the needs of a wide range of industries and applications. Our available types of industrial valves include:

Industrial Butterfly Valves

Butterfly valves are shut-off valves that feature a relatively simple disc design. In the open position, the disc is moved out of the way and allows fluid to enter and exit the valve. When placed in the closed position, it prevents fluid from flowing through the valve.

These valves are suitable for fluid systems that require quick operation. Additionally, their simple, compact, and lightweight construction make them affordable and functional options for limited-space use cases. Typical applications for butterfly valves include use in water supply, wastewater treatment, gas supply, pharmaceutical, and food and beverage processing, chemical and oil, and power generation equipment and systems.

For additional information on these valves and the types we offer, visit our butterfly valves product page.

Universal Butterfly Valves

Universal butterfly valves are a variation of standard butterfly valves that allow for fewer disc positions. They integrate a spring-loaded latch lever to help set the flow control position. Industries that commonly employ this type of valve include the pool and spa industry.

For additional information on these valves and the types we offer, visit our universal butterfly valves product page.

Ball Check Valves

Ball check valves contain a ball that moves up and down inside a conical chamber using rails. Flow pressure lifts the ball, allowing fluid to flow through the valve. However, gravity causes the ball to return into place when the flow stops, preventing backflow.

These simple, low maintenance valves require an upward flow piping system to work properly. Typical applications include use in pumping stations with infrequent attendance and maintenance.

For additional information on these valves and the types we offer, visit our ball check valves product page.

Swing Check Valves

Similar to ball check valves, swing check valves are valves that prevent backflow. They feature a design that uses a hinged disc to start or stop flow. The hinge design allows for flow in only one direction; the movement of fluid in one way opens the valve, while movement in the other way closes it. In contrast to butterfly valves, these valves do not require external activation.

Common use cases for these valves include water and wastewater pumping systems.

For additional information on these valves and the types we offer, visit our swing check valves product page.

Wafer Check Valves

Wafer check valves operate similarly to swing check valves, allowing for fluid flow in only one direction. The flow of fluid through the valve lifts the thin wafer component off the seat. Flow in the other direction allows it to fall back into place to stop fluid from entering or exiting.

The unique wafer design makes them less likely to clog than ball check valves and suitable for horizontal or vertical mounting. Additionally, they require less back pressure to close.

These valves find application across a diverse set of industries, including chemical processing, mining, power generation, and water treatment. They are commonly used in tank inlet/outlets, pumps, mixers, and process intake systems.

For additional information on these valves and the types we offer, visit our wafer check valves product page.

True Union Ball Valves

True union ball valves use an open/close operation and can be activated manually or with a remote electric or pneumatic actuator. In addition, the safety block function doesn’t allow the ball to float downstream on pressure surges. TVI carries valves that are rated up to 235 psi, while other manufacturers only offer valves with a max of 150 psi. Our valves also include a 2 year warranty, ensuring long lasting quality and dependability.

For additional information on these valves and the types we offer, visit our true union ball valves product page.

Compact Ball Valves

Compact ball valves are ball valves with a smaller footprint that employ a lever actuator in place of flow actuation. Lever actuation either opens the valve or shuts off flow. These small plastic valves are suitable for any piping systems with limited space requirements.

For additional information on these valves and the types we offer, visit our compact ball valves product page.

Flange-Type Diaphragm Valves

Diaphragm flange valves are another type of unidirectional flow proportional valve that allows throttling and flow control. They use weir design diaphragms arranged in such a way as to allow for flow from downstream fluid pressure. The diaphragms collapse and close the valve against backflow pressure. This design helps provide bubble-tight sealing even in slurry and suspended particle applications.

Diaphragm flanges are often used in chemical processing to throttle the flow or as a flow control device.

For additional information on these valves and the types we offer, visit our flange-type diaphragm valves product page.

Y-Sediment Strainer Valves

Y-sediment strainer valves help remove suspended solids and impurities in pumps, meters, and other fluid system components. They allow industry professionals to easily flush out accumulated solids during cleaning operations.

Common applications for these valves include chemical processing facilities, aquariums, mining operations, water treatment plants, and landfills.

For additional information on these valves and the types we offer, visit our Y-sediment strainers product page.

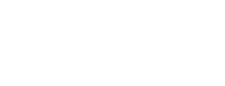

Which Valve Is Right for My Need?

When choosing a valve for your fluid handling and processing applications, there are several factors to keep mind, including:

Type and Size

The intended function of the valve largely determines what type you should choose. Some of the basic functions that a valve can perform are:

- Adjusting, diverting, or stopping flow

- Mixing fluids

- Relieving pressure

- Preventing backflow

Depending on which of these functions you need the valve to perform, certain types may be better suited for your application than others. In addition to selecting the proper type, it is necessary to choose the size that best fits your system.

Construction Material

Select a construction material that is compatible with operating conditions of your system. Thermoplastic valves offer a lightweight, low-cost option that exhibits longevity, corrosion resistance, resistance to cavitation, and broad chemical compatibility. In addition, TVI carries a selection of metal valves with PFA lining, combining the strength of a metal valve with the advantages of a thermoplastic valve.

Performance Requirements

In addition to performing the function required and being compatible with the fluids in the system, a valve must meet the performance requirements expected. Regarding valves, the two most common performance indicators are temperature and pressure. Refer to the particular valve to ensure it meets your requirements in those areas.

Maintenance Requirements

Some valves require maintenance to continue providing reliable and stable performance. While most thermoplastic valves require little to no maintenance, you’ll want to consider any maintenance requirements and whether the particular application it will be used in lends itself to any maintenance and repairs. Consult our operations and maintenance guide for more information.

Specialty Requirements

Some valves, such as check valves, have special requirements. For example, when using a check valve in a fluid handling or processing system, you need to determine the following:

- Response time

- Cracking pressure

- Normally closed vs. normally open design

- Vertical vs. horizontal mounting

- Flow direction relating to fluid density (upward or downward)

Partner with TVI for High-Quality Plastic Valve Solutions

Considering the five factors above and evaluating which valve best suits your needs can be daunting. However, TVI is here to help.

With over 30 years of experience in valves, our expert team has the knowledge and skills to help you select the ideal valve solution for your application. For general information about valves, contact us today. If you have questions about a particular valve we offer, request a quote.