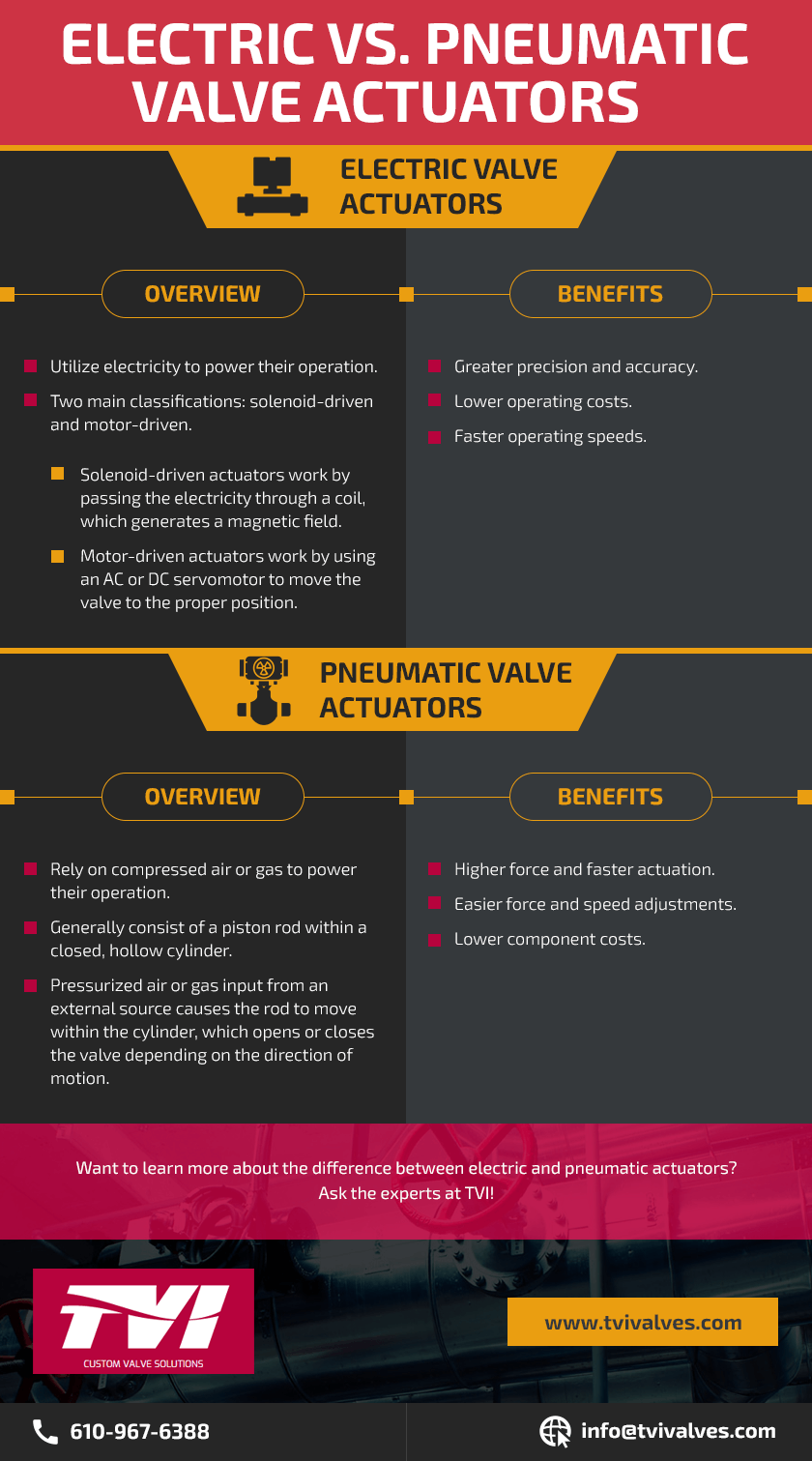

Electric vs. Pneumatic Valve Actuators

Valves play an essential role in many industrial and manufacturing processes. By fully or partially opening and closing passageways in piping and tubing systems, they help direct and control the flow of liquids, gases, and steams needed for various operations. This function can be conducted manually through the use of a gear, handle, lever, or wheel or engineered to occur automatically in response to changes in flow, pressure, or temperature.

Automatic valve assemblies utilize actuators to open and close the valve. These mechanical devices can be powered in several ways, including electrically, pneumatically, and hydraulically. Each option offers distinct advantages and disadvantages that make it suitable for different applications. Below, we provide a comparison between electric and pneumatic valve actuators, highlighting what each one is, what benefits it offers, and what applications it is typically used in.

Overview of Electric Valve Actuators

Electric valve actuators utilize electricity to power their operation. They can be categorized into two main classifications: solenoid-driven and motor-driven. Solenoid-driven actuators work by passing the electricity through a coil, which generates a magnetic field. The magnetic field is then used to move the valve stem, which adjusts the position of the valve disc. Motor-driven actuators work by using an AC or DC servomotor to move the valve to the proper position.

Some of the advantages of electric valve actuators include:

- Greater precision and accuracy. They offer highly accurate and precise positioning control. Once the intermediate and stop positions are programmed into the assembly, the actuator will position the valve accordingly in response to the specific inputs.

- Lower operating costs. They require less maintenance and repair over time, which can result in lower overall costs across their lifetimes.

- Faster operating speeds. They have some of the fastest movement speeds of all actuators (up to 10 m/s).

These valve actuators are commonly found in excavators, forklifts, and dump trucks. Other typical uses include factory robots and other automated manufacturing systems.

Overview of Pneumatic Valve Actuators

Pneumatic valve actuators rely on compressed air or gas to power their operation. They generally consist of a piston rod within a closed, hollow cylinder. Pressurized air or gas input from an external source causes the rod to move within the cylinder, which opens or closes the valve depending on the direction of motion.

Some of the advantages of electric valve actuators include:

- Higher force and faster actuation. They can generate pressures up to 40,000 lbs. and achieve open/closing speeds as fast as 2 m/s.

- Easier force and speed adjustments. They are easy to adjust for different forces and speeds.

- Lower component costs. They are available at relatively low price points. Additionally, replacement components are generally inexpensive.

These valve actuators are ideal for applications where an electrical power source is not available or safe (e.g., environments with flammable or ignitable compounds). Typical uses include internal combustion engines, pumps, and ventilation systems.

Electric and Pneumatic Valve Actuators at TVI

Want to learn more about the difference between electric and pneumatic actuators? Ask the experts at TVI! As a leading provider of quality valves and valve accessories, we are well-equipped to answer and address any questions or concerns you may have about valve parts and products. Additionally, we can help you identify the ideal valve actuator solution for your systems and applications. All of our valve actuator products are mounted and tested to ensure optimal performance so that you can rely on them for your most critical operations.